Orange, Massachusetts isn’t exactly a hotbed of local food. It’s hard to make a living farming anywhere, but it’s especially so on the rocky, ridge-and-valley terrain that makes up the North Quabbin region. The landscape’s intense topographic variability keeps farms from growing very large, and the glacial tilth coughs up enough stones each year to turn many farmers away from vegetables and toward livestock instead.

In rural New England, farming small isn’t a political choice. It’s a matter of necessity. Far from urban market hubs, these farm communities struggle to access the resources they need to make a local food economy viable. Acquiring the capital and supplies necessary to grow food is difficult enough. But for remote farmers and the provincial retailers that support them, it’s even harder to support the equally crucial step of getting that food to a customer.

Direct marketing techniques like CSA and farmers’ markets, darlings of the local food movement in more urban settings, don’t work very well in this context. In the first place, finding staff for that market or CSA is expensive, whether in dollars paid to an employee or in farmers’ time lost waiting for customers to come by. Traditional wholesale would be a much better fit for Orange’s farmers, but they’re simply not big enough to provide the consistency and volume required by such buyers. When it comes to sales, they’re caught between one of the North Quabbin’s abundant rocks and a hard place:

Not only are customers lukewarm on going out of their way to buy on-farm, but the town’s more traditional farmers lack the infrastructure—and bandwidth—to support the logistics.

That’s especially true for small livestock farmers, who face another hurdle: With a population of fewer than 10,000 people, many of whom possess sensibilities (and budgets) more aligned with Walmart than Whole Foods, Orange yields few customers willing to go to the expense or effort associated with finding and preparing local meat.

What do you imagine is a small livestock farmer’s most difficult task? I’m willing to bet you didn’t say finding a place to store their frozen goods after slaughter or for the length of a market or CSA season. But when it comes to meat, storage space is paramount. And financing a commercial freezer is costly—often starting at $25,000. Small local food retailers have a similar problem: They’re often short the cash flow needed to maintain a large inventory of an expensive specialty product like local meat.

Also working against the odds to make a local food economy float in Orange is the Quabbin Harvest Food Co-op. Founded in 2009 when there was only one other grocery store in the region, the Co-op strives to connect local eaters with local producers. But like the farmers it seeks to support, Quabbin Harvest is limited by the buying power of this sleepy former-mill town. Cash flow is tight—very tight—and keeping shelves stocked is a constant struggle. Low inventory means fewer customers, fewer customers means less cash flow, less cash flow means low inventory: it’s a frustrating and seemingly self-defeating cycle.

Inside the Quabbin Harvest Food Co-op

Rather than calling it quits, though, Quabbin Harvest is trying something new. It’s keyed into a relationship between its under-stocking woes and the difficulty local farmers face in storing and selling their meat. The Co-op hopes both problems can be helped by one solution: a consignment program for frozen meat.

Consignment is a sales mechanism typically used for non-perishable goods, like works of art or clothing. In this scheme, a producer—say, a potter—agrees to display her goods at a retailer without receiving payment until an item sells. Pottery doesn’t go bad, so the store can keep pieces for as long as necessary, all the while providing the potter with a point of access to potential customers that she doesn’t need to manage herself. The store can also stock more of these pieces at once than it would otherwise be able to afford because it gets to pay gradually over time, as the pieces sell.

That’s how Quabbin Harvest’s consignment program started, says Cristina Garcia, a former board member. “First we were consigning crafty artisan stuff. Then we had the idea to expand into shelf-stable foods, like honey and ghee.” This seemed to work well, helping to keep the co-op’s shelves attractively full without tying up scarce cash flow. So when a farmer approached the Quabbin Harvest looking for a place to put his freshly slaughtered steer, they thought they’d see if consignment could work for frozen meat as well.

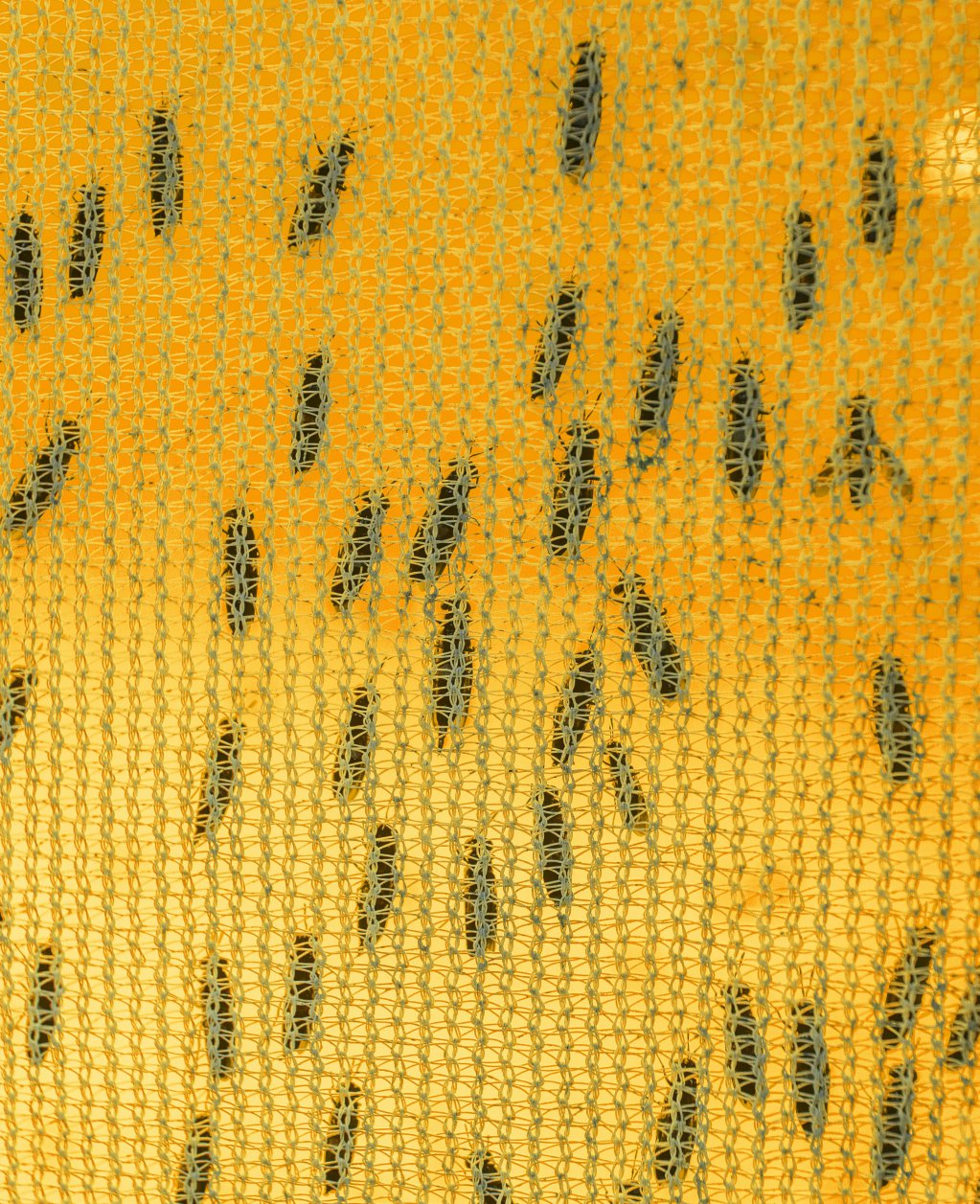

Facebook/Quabbin Harvest

Facebook/Quabbin Harvest The small-scale meat share economy

“Local meat is one of the best-selling items at the co-op,” says Amy Borezo, board chair emeritus and current volunteer store manager at Quabbin Harvest. Despite the co-op’s tiny size, “we’re a leader in the region in terms of the amount, quality, and variety of local meat we offer,” she says. As such, it’s important to the co-op’s bottom line that it’s able to keep its freezers full.

The farmer who initiated the program thought his cow “might as well be in one of our freezers, on display, as in his own,” Borezo recalls, and he didn’t mind if he didn’t get paid until it sold. Soon, Quabbin Harvest began offering the consignment option to other local farmers like John Moore, who produces beef, vegetables, hay, and maple syrup on farmland that’s been in his family for more than a century. “I’ve done business with the co-op for years,” he says, and consignment ended up being “just the way it worked out. Sometimes I was pretty lax with the receipts and would let them pay later.” Eventually, the structure became more formalized.

Moore acknowledges that there are benefits to traditional wholesale relationships that consignment lacks. “It’s nice to show up with your stuff and just get paid right then and there.” But so long as he can count on the payment once his meat moves, he says, “I’d be happy to keep selling that way.” And while Moore doesn’t rely on the co-op’s freezer space for storage—his three chest freezers can accommodate the meat he produces—his son, Dan Moore, does. “Dan will take three or four animals, beef cows, to slaughter at once. So it’s nice for him to be able to put a whole half-a-steer in their freezers.”

Quabbin Harvest / Facebook

Quabbin Harvest / Facebook Chase Hill Farm meat in Quabbin Harvest’s freezers

Nora Weaver also sells meat to Quabbin Harvest on consignment. Weaver is the CSA manager at the Farm School, a diversified animal and vegetable operation one town over that offers educational programming for both children and adults. Once the Farm School’s meat CSA is finished for the season, Weaver has to find a home for any remaining cuts. “The co-op approached us about a consignment arrangement,” she says, and she thinks the idea makes a lot of sense. “The product is frozen, so whenever they sell it is great.” And because of the Farm School’s unique position as a non-profit educational farm, “we can afford to postpone receipt of payment.”

Just because an idea makes sense doesn’t mean it’s easy to execute. Borezo, Moore, and Weaver all say that in order for a consignment system to succeed, it’s essential that the retailer have a watertight system for tracking inventory and payment. Knowing whose product has sold and making sure that person gets paid promptly is key to maintaining the trust and accountability that form the backbone of a consignment agreement. It’s in this particular area that a small co-op in a remote, rural community might actually have a leg up on burlier retailers in more populous—but more impersonal—settings. In a town where everybody knows everybody, it’s hard to do somebody wrong and get away with it.

“It’s about relationships,” Borezo says. “That’s how we’ve managed to stay afloat so far.” Because the co-op knows its farmers intimately, “we can be flexible and nimble in finding interesting solutions” to their dilemmas. “It’s really pretty exciting.”

Borezo hopes the meat consignment program at Quabbin Harvest expands. It’s great for its cash flow, and having a consistent meat inventory also helps sales overall. “For some farmers, it seems like we sell more of their meat than they can,” she says, “so it makes sense for both parties.”

Garcia agrees consignment “definitely works for the co-op.” Beyond just the financial stability it offers, the program is helping Quabbin Harvest become better integrated into the local food scene in Orange. Farmers who sell on consignment join as members, which is “hugely beneficial,” she says. The stronger the membership base, the stronger the community investment, and the stronger the co-op—and the farm community it supports—becomes in turn.

In his book The Unsettling of America, Wendell Berry wrote that America’s so-called farm “experts” are genius in their ability to “take a solution and divide it neatly into two problems.” By recognizing the complimentary nature of their respective surpluses and scarcities, the people in Orange are attempting to do just the opposite. Quabbin Harvest and local farmers each possess half of a lopsided equation. The meat consignment program connects those fragments with each other, bringing one small part of a local food economy into balance.

Correction: An earlier version of this story incorrectly identified Nora Weaver as Nora Wheeler. We regret the error.