Chris Lozier

“If you wish to make an apple pie from scratch, you must first invent the universe.” —Carl Sagan

Local beer takes more than a taproom. Just as bakers need flour for bread, brewers need malted grains to brew. The problem is there’s a scarcity of local malthouses—the facilities that germinate grains, so brewers can use the starch to feed fermentation. If you want to make truly local beer, don’t start a brewery. You’d better get busy and build a malthouse.

The trouble is twofold, and began as the grain belts developed in the late 1800s, moving grain production, and therefore key intermediate processing facilities, like mills and some malthouses, out of locales. Then, Prohibition acted like a broom, sweeping away small breweries and the remaining malthouses. When American beer came back, it came back big—and the malt industry, today, is highly concentrated. Even craft breweries use malt from only a handful of global companies; the smallest of the large malters work in batches of 150,000 pounds. Craft malting, meanwhile, is an industry in its infancy. A decade ago, pioneers retooled existing equipment like dairy tanks to make malting systems; the DIY feel persists even as food processing and beer equipment manufacturers are only beginning to design and build for maltsters.

Chris Lozier

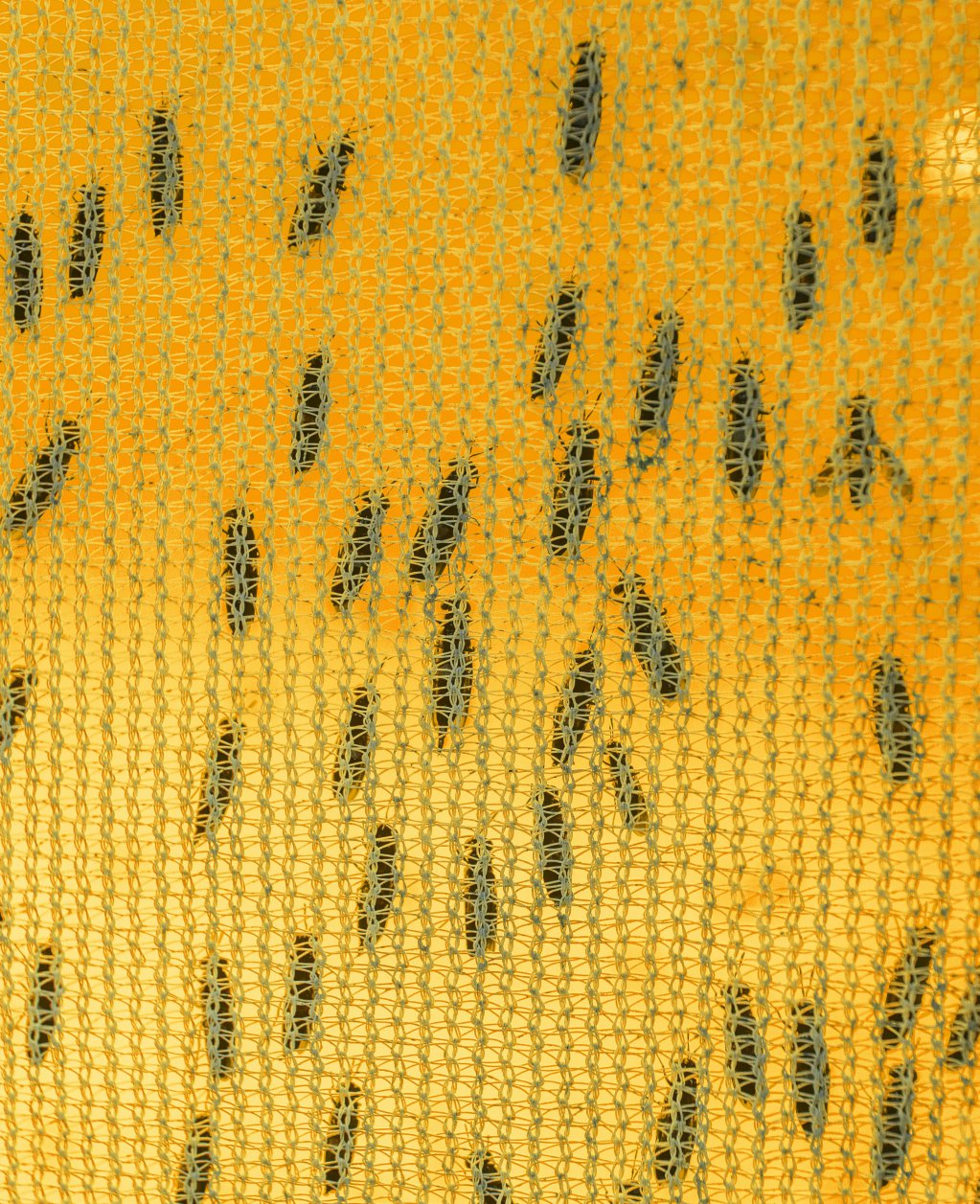

Chris Lozier Palouse Pint is a new malthouse in Spokane, Washington. Above, the eponymous Palouse

“Right now, there isn’t really a malting company in a box. You can go to the Brewers Conference and if you have a million dollars you can buy equipment to start a brewery. There is not that equivalent for malting,” says Mary Palmer Sullivan from the Washington Grain Commission.

But a craft malting culture is growing in North America. There are 59 craft malthouses, and another 50 in planning or under construction. And one of them, Palouse Pint, is in Spokane, Washington, far from the farmers’ markets of Seattle and Portland. This is the Inland Northwest, worlds away from the groovy affluence of the I-5 corridor. It’s farm country, and the world’s highest yielding dryland wheat region—some areas are so dry that growers let fields lay fallow every other year, gathering up every precious drop of rain. The tallest structures are grain elevators, and giant gray silos hulk over small towns, the only skyscrapers around.

Farming is a way of life in many areas outside the city of Spokane. But here, as is the case in much of rural America, there is very little connection between what people grow and what they eat.

Chris Lozier

Chris Lozier Maltster Joel Williamson and farmer Bill Myers of Joseph’s Grainery salute the field with a beer

Today, LINC Foods, which stands for Local Inland Northwest Cooperative, is in the malting business—but that came about almost by accident. It happened because Robinette met her business partner, Joel Williamson, through their shared interest in social change, which led each of them to the Bainbridge Graduate Institute in Seattle. As they finished their education, they decided to tackle something together in Spokane.

A city council member got a group of people together to investigate how local foods could drive the local economy. There was talk of forming a food policy council. Gonzaga University held a meeting with farmers, and the two were invited to that too, because they were gaining a reputation for being experts in the field, even if their expertise was mostly curiosity.

Chris Lozier

Chris Lozier Cofounder Beth Robinette perches on the malting system

“We thought that was a good indication that we should do this,” says Williamson. He and Robinette took the most interested farmers and got serious, figuring out what kinds of services to provide growers and buyers. They formed a board and incorporated as a co-op in August 2014.

The early stages were just filling up a Scion in a parking lot with produce, and helping to distribute it, figuring out how to overcome the barriers Gonzaga had for procurement, and seeing what public school districts could purchase.

“We were scrambling, trying to find supply for the demand we had, or meet demand for the supply we had. We learned a lot about what else we needed to do. Learning by doing is painful but it works,” he says.

Soon, LINC Foods started working out of the local food bank, which offered it access to cold storage for free. The food bank appreciated their effort, and had some extra space, so they set some ground rules for collaboration, and the cooperative relied on their infrastructure for two years.

In the meantime, the founders were still busy accumulating knowledge and tools, and were enrolled in a program at the University of Washington in Seattle, the Buerk Center for Entrepreneurship’s Jones & Foster Accelerator. This intensive mentoring process had a prize of $25,000 for completion. The cash was very alluring, an amount that could address the need for their own warehouse space and delivery truck. But the process itself proved at least as useful because that’s where they came up with the idea for the malthouse.

The accelerator forced them to get realistic about business plans. They saw they’d have to pad the financials to support the enterprise through what they predicted would be five lean years. Doing some type of food processing seemed like the way to add value to operations, but once they looked into processing carrots into baby carrots or coins for institutions, or making berries into jams, they realized the equipment was too expensive and the margins were too thin. Williamson, however, happened to be a home brewer. And they were surrounded by all that grain, so how about malting? The potential profits for malt were more attractive. And the panel of mentors at Jones & Foster loved the idea.

Less than a year after they’d incorporated the cooperative, the two went to their membership and proposed starting a malthouse. The idea was received with some skepticism. How would malt serve the cooperative, whose members were mostly growing fruits and vegetables? And did a startup—already precarious—really need another startup stacked on top? Robinette and Williamson were able to state their logical case, and began pursuing the secondary enterprise: a malthouse called Palouse Pint.

Chris Lozier

Chris Lozier The finished product: A beer

The co-op collaborated with food equipment manufacturer GEM in Portland, Oregon to create a drum-style system that handles three- to five-ton batches of grain. The shared design partnership was useful, and reflects how, in the world of “small malt,” everything is an invention: from the seed varieties growers choose for different malting and brewing characteristics; to the relationships between growers and maltsters, and maltsters and brewers; and to all the physical tools and logistics required to handle materials and make those relationships possible.

Long before he started plotting what size and style malting system LINC should create, Joel Williamson went to malt school at the Canadian Malting Barley Technical Center in Winnipeg. The short course is geared to the rising craft malt industry, and covers the basics of making malt. In another educational effort, Williamson joined the Craft Malting Guild, a small North American member organization that’s helping define the craft malt industry.

For financing, LINC needed $600,000 for the malthouse, and borrowed half from The Working World, a non-profit which makes loans to worker-owned cooperatives. The other half of the capital comes from local investment. LINC Foods developed a structure for this investment with the help of Equal Exchange, and had gatherings to bring together people in the community. People were enthusiastic about the project, and still are.

Thomas Croskrey of Bellwether Brewing Company is among the fans of Palouse Pint. He runs a brewery in Spokane and likes the echo beer can make of history and place.

“Historically, brewers were not importing any ingredients,” he says. “They were using what was on the farm, in the forest, what was available.”

Croskrey is excited to explore terroir and loves supporting the local economy. He’s fond of the Carmel 40 from Palouse Pint, and is finding a place for it, and for triticale (a cross of wheat and rye) and white wheat malts, in his beers. He would use more, except customers aren’t asking about local malt as much as he thought they would.

While Croskrey likes to experiment as a brewer, he finds that customers head for the familiar. Smaller malt production means variations, but customers tend to want the IPA they had the last time, not another play on the style, once they’ve found a beer they love. Intellectually, people might want something different, but they tend to buy the same things again and again.

These Palouse Pint malts are made from grains grown by Joseph’s Grainery, a farm that is a member of the cooperative. Bill Myers and his family grow 3500 acres of grain and bean crops, and have a small line of flours and cereals they market themselves, and LINC Foods also distributes.

Chris Lozier

Chris Lozier Bill Myers of Joseph’s Grainery at Palouse Pint

“My hope and dream is to run the whole farm through the mill as opposed to the truck and barge hauling it to the export market, or to the feed market in the Tricities and Walla Walla,” says Myers. “It’s a ways off but it’s coming.”

The barley and malt bring that dream one step closer. Shipping cereal crops all over the world seems silly to him, especially when the costs of production are higher than prices on the commodity market. A 1973 bushel of wheat that sold for $4 should sell, on an inflation index alone, for $20. But wheat is at or below that $4 mark. These prices are driving a number of farmers to seek alternatives.

Demand for contract malting has turned out to be an unexpected opportunity of the undertaking at Palouse Pint. The plan had been to create and market their own brand of malt, but several farmers have come with their grain looking for a custom line, and the malthouse is going to be very busy this year making malt for clients.

James Wahl is a fourth generation wheat grower, who switched to growing triticale.

“We always made the joke about farming: sometimes it’s a lifestyle, sometimes it’s your income. Hope that there isn’t three lifestyle years in a row,” Wahl says.

Chris Lozier

Chris Lozier Until recently, local malthouses have been few and far between. Now, drinkers may taste a little “beeroir”

Two years ago, he stopped growing club and white wheats and started growing triticale for a seed contract. By raising something unique, and pursuing value-added options like malting and flour, he’s got a chance to break out of the losses in the wheat market. The new business, MJW Grain, is named for his daughter, Maya Jane. Currently, the family has 2700 acres in cropland and 1900 acres fallowed. Changing gears is working well as a business so far, and in the next few years, Wahl and his family hope to switch from petroleum-based fertilizers.

The Spokane malthouse contract malted Wahl’s triticale, and he carries around 25- and 50-pound bags as his business card, bringing them to distillers and brewers.

To be clear, the scale of the opportunity for grain growers to use this malthouse is limited. The most a 5-ton malting system can handle in a year is grain from about 50-200 acres, depending on yield, which varies by grain variety, and by growing conditions each season. This is a drop in the bucket for grain growers, but a welcome alternative to dropping crops into the bottomless pit of the commodity system. Growers can start to establish an identity for themselves. They can make choices about how to reconfigure what they grow and improve what they earn. And, in the bargain, reconfigure a grain system.

That system’s constraints are hard for non-farmers to appreciate. Grains are a global market, with rules that govern everything from the ground to the glass. Invitations for growers to step out of those constraints suggest changes in agriculture, business and personal relationships, ecology and economies all along the supply chain.

LINC Foods is very young but already finding its footing. Their first year, they were able to help farmers earn $20,000. Last year, they directed $190,000 to farmers. The cooperative’s board went on its retreat in January feeling secure in its accomplishments, and ready to explore more possibilities. And the year is brand new for the brave new world of off-grid malts, too.