iStock / LouisHiemstra

Indoor farming companies—like Kimbal Musk’s Square Roots—claim their methods can replicate any climate on earth, resulting in better-tasting produce. That story may be more marketing than science.

It may have been cold and gray in New York, but inside a shipping container in Brooklyn, it was as warm as a summer day in Italy—the ideal climate for growing Genovese sweet basil.

That’s what Kimbal Musk, co-founder of the indoor farming company Square Roots, told me when we met after an event at the Food and Finance High School in Manhattan last December. Though he’d just appeared onstage with the musician Questlove, I wasn’t there to ask him about Questlove’s new cookbook, to which Musk—a chef and restaurateur—had contributed a recipe. I was there to learn about his company’s line of bespoke, hand-harvested herbs, which are grown inside shipping containers in Brooklyn (and at a second “farm campus” in Grand Rapids, Michigan).

Specifically, I wanted to know about flavor. Square Roots claims to “recreate ideal growing climates from around the world” for its basil, mint, and chives to thrive in. According to Musk, these intensively managed indoor environments can be fine-tuned to recreate, and even improve upon, the best-tasting herbs planet Earth has ever had to offer.

The interview took place in a classroom. Wearing a brown suede jacket, black and white sneakers, and his signature straw cowboy hat, Musk—the brother of billionaire entrepreneur and Tesla founder Elon Musk—looked the part of a future-of-food emissary.

The interior of a shipping container basil farm operated by Square Roots, a Brooklyn-based indoor farming company growing hand-harvested herbs

Square Roots

“We can replicate any climate in the world,” he said. “We actually replicate Genoa, Italy, for growing our basil. And it’s not any part of the year—it’s the month of June, in 1997.”

According to Musk, June 1997 was a banner season for Genovese basil. Why settle for good growing conditions when you can have the best there ever was?

“That was the perfect year,” Musk continued. “That’s how precise you can get it to. And you can get the humidity and oxygen levels, carbon dioxide levels to, you know, within half a percent.”

“By giving plants exactly what they want, we can make them taste how they should.”

As indoor farms have proliferated in recent years, so have claims like these. The promise of these facilities—which are part of a larger category of food production called controlled-environment agriculture—is being able to create the optimal growing conditions for plants throughout their life cycle by manipulating the temperature, humidity, carbon dioxide level, nutrient mixes, and light spectrum and intensity. This is in contrast to conventional crops, which are still subject to the vagaries of weather, good, bad, or disastrous. Inside Square Roots’ growing containers, nothing is left up to chance.

[Subscribe to our 2x-weekly newsletter and never miss a story.]

“It’s just amazing what we can do,” Musk elaborated in a follow-up phone interview in January. “You can actually design the lights to, say, I’d like the leaf of this to be a little bit bigger, or a little smaller, or I’d like the softness of the leaf to be a little softer or a little crispier, or I’d like the oils to increase or I’d like the oils to decrease, depending on what you need.”

Square Roots is far from the only indoor farming company making total environmental control a part of their marketing pitch. The CEO of Bowery Farming told CNBC that his company can grow kale with a softer leaf or a more peppery arugula. The chief executive of 80 Acres Farms told The Washington Post he can grow two types of basil from the same seed—a sweeter herb for the grocery store and a stronger version for chefs—simply by tweaking environmental factors. Fresh Impact Farms’ business model—before the pandemic, at least—was growing customizable herb and flower garnishes for restaurants. The company’s website features an indicative tagline: “Harnessing the power of technology to invigorate the emotion of flavor.”

Left, a Square Roots employee harvests Genovese basil. The company’s co-founder, Kimbal Musk, has claimed that Square Roots replicates the climate of Genoa, Italy, in June 1997, for growing its basil.

Square Roots

These claims about the links between climate and taste may sound fantastical, but science backs them up—to a point. Changing light color, intensity, and duration has been shown to influence plant growth and development, as well as shape, size, and color. Different light recipes can even increase the volatile compounds that determine how plants smell and taste.

Still, fact-checking specific claims—for instance, whether Square Roots’ basil tastes anything like basil grown in Genoa in June, 1997, or even whether the growing conditions really approximate Genoa in 1997—is difficult, if not impossible. Indoor farming companies keep their cards close, reluctant to let any bit of intellectual property slip out, or to open themselves up to outside scrutiny. Some companies won’t even allow press on site or share photos of their farms with the media in order to protect their intellectual property. And then there’s the fact that many of the wildest claims revolve around flavor or taste, which is still not fully understood by sensory scientists. It’s hard to know where the science ends and marketing begins.

That hasn’t stopped money from flooding the indoor farming space. Newark, New Jersey-based Aerofarms, which claims it’s setting “a new culinary standard” with greens grown in peak-season conditions all year round, has raised $238 million. Plenty, a San Francisco-based startup which claims its greens have “unparalleled flavor,” has raised $401 million, and counts Jeff Bezos and Google co-founder Eric Schmidt among its backers, puts it simply: “By giving plants exactly what they want,” the company writes on its website, “we can make them taste how they should.”

The implication is always that a more flavorful future is on the horizon. But is it?

—

An aerial view of Square Roots’ Brooklyn operation: ten shipping containers in the parking lot of the Pfizer building

Square Roots

The shipping container is parked along with nine others in the lot next to the Pfizer building, a former chemical plant in Brooklyn where Square Roots is headquartered. When I visited on a brisk January afternoon, Paul Berry, Square Roots’ head of engineering, gave me a brief tour of one of the company’s shipping container farms, which it calls “climate farms” for their ability to fine-tune the environment enclosed within. He opened a door to the basil container and we peered through a protective veil of glass.

Dark green herbs covered the walls, sprouting from vertical planters. The basil on one side was lush and full, almost ready for harvest, while the rest needed more time. A center divider housed a bank of lights, but they were dark; Berry said night and day are reversed in the containers so that farmers don’t have to work under a harsh glare. He explained that a mixture of water and fertilizer periodically drips down through the planter towers and soaks the basil roots in their soilless growing medium—simulating rain, or something like it. While we stood there talking, a smaller set of lights flickered on over a tray of seedlings in the back, in the plant nursery. Indoor farms mostly use light from the red and blue spectrums, which promote photosynthesis, so the light had a bright pink hue.

Square Roots controls every condition within that shipping container: the temperature, humidity, carbon dioxide levels, nutrient mix, and light spectrum and intensity. While greenhouses rely primarily on sunlight, sometimes supplemented with growing lights, indoor farms are lit entirely by artificial lighting. This kind of agriculture has largely been made possible—and financially viable—by the increased efficiency and plummeting cost of light emitting diodes (LEDs) over the past decade.

In imitating Genoa, Square Roots is trading on what wine producers call “terroir,” or what the American wine writer Matt Kramer has called its “somewhereness.”

Although recreating sunlight with electricity comes with significant financial—and environmental—costs for indoor farms, it does open a number of possibilities. Square Roots can grow summer crops like basil year-round, and by simulating peak-season conditions has managed to greatly decrease growing times: Berry said the complete lifecycle of Square Roots’ basil is a mere 30 days from seed to harvest, which is very fast. For comparison, grown outside, basil can take up to 30 days just to germinate, or sprout.

But is it really like 1997 Genoa on the other side of the glass?

Not exactly. Musk’s cofounder, Tobias Peggs, later told me that Genoa is really more of a “baseline.” He said Square Roots will talk to chefs or look online to see where in the world the best basil is grown, and when in the last few decades the herb was “really, really fantastic.” Then they’ll look at the climate data from that season—at the temperature, the time the sun rose and set—and try to replicate that environment inside the containers.

“But that’s just the start, right, because from there you then improve,” said Peggs. So while Square Roots may have started with Genoa, it has since iterated on what nature and history provided.

Those iterations turned out to be modest. During my visit, Berry said that they were growing basil at two different temperatures, one significantly hotter than the other, to see what happened—amounting to a basic A/B test. Musk had described these efforts in more dramatic terms, suggesting that each container added to the company’s research and development capacity.

The complete lifecycle of Square Roots’ basil is a mere 30 days from seed to harvest. For comparison conventional basil, grown outside, can take up to 30 days just to germinate.

Square Roots

“In Brooklyn, we have 10 farms, which really means we have 10 experiments going on at any one time, at least,” he said.

Even if Square Roots could conduct ten experiments at once, scientists say there are limits to that approach. Just like conventional fruit and vegetable breeders, indoor farmers may find that changes that improve taste have a negative impact on yield or shelf-life, or that making plants grow faster lowers nutrient levels. In other words, promoting one desirable parameter may have unintended consequences for another key trait.

“Maybe a certain light source or certain light recipe could increase the pepperiness or the bitterness or whatever they’re looking for,” Erik Runkle, a professor in the Department of Horticulture at Michigan State University and project director of OptimIA (Optimizing Indoor Agriculture), a Department of Agriculture-supported Specialty Crop Research Initiative, told me in a phone interview. “It’s just whether or not other things that change at the same time would still be desirable. So you can steer it, of course, but only to an extent. You can’t, you know, you can’t turn a banana into an apple.”

Harry Klee, a horticulturalist at the University of Florida who studies why fruits and vegetables taste the way they do, said it even more plainly: “If someone is telling you it’s all about light, they’re probably on drugs.”

—

In imitating Genoa, Musk and Peggs are trading on what wine producers call “terroir,” or what the American wine writer Matt Kramer has called its “somewhereness.” They are not alone in this: The vertically farmed strawberry company Oishii, for instance, seeks to recreate “the ideal natural ecosystem of Japan’s most distinguished strawberry-producing regions.”

Terroir is often assumed to be the earth itself—the soil in which the grape vines grow—but there are other factors too, from altitude to humidity to airflow, some of which could possibly be quantified and replicated indoors. (Flavors that are derived from soil are probably off the table; virtually all indoor farms use a soilless growing medium.)

Whether terroir is even “real” or not is a passionate and ongoing debate among winemakers. But indoor farming companies want to have it both ways: To assert that there are superior regions and climates for growing specific produce, and also that those conditions can be replicated in a box. It’s one thing to suggest that the Italian coast imparts certain qualities to basil. But then shouldn’t the inside of a sealed shipping container taste like something too? Can an herb’s “somewhereness” be convincingly faked? Or will it yield instead a kind of “anywhereness”?

Can an herb’s “somewhereness” be convincingly faked?

Then there’s the question of empirically evaluating taste, or flavor. Who is in charge of determining if and when one of Square Roots’ experiments results in better-tasting basil?

“This is a classic issue with sensory science,” said Beverly Tepper, a sensory scientist at Rutgers University. “You have somebody in the organization who makes a decision about whether something is good or bad and whether it should be packaged and shipped without actually having, I would call it evidence-based information about what exactly does it taste like.”

https://www.instagram.com/p/CFfuTHLg4BU/?utm_source=ig_web_copy_link

Evidence-based information could include evaluation by a panel of experts “trained to recognize different aromas, flavors, textures, taste in a specific food product,” Tepper explained, or consumer tasting panels.

One of the few companies to be conducting such experiments in a rigorous, semi-public way is AeroFarms. In 2017, AeroFarms and Rutgers received a $1 million grant from the Foundation for Food and Agriculture Research to study the flavor and nutritional content of baby leafy greens.

Tepper, one of the researchers working with AeroFarms, said one class of nutritional elements they’re looking at are glucosinolates, a compound that has a bitter and astringent taste. If someone doesn’t like kale or broccoli, glucosinolates might be to blame.

“They’re health-promoting compounds, which is good, but if you drive them too high people won’t want to eat them,” said Tepper. “So what we’re trying to do is to find that sweet spot where you can drive the chemistry to a certain level and get the highest nutritional value while also making these plants very acceptable to people.”

Tepper and her fellow researchers at Rutgers are taking samples of baby leafy greens from AeroFarms and giving them to an expert panel trained to identify different aromas, flavors, and textures. At the same time, her colleague James Simon in the plant biology department is analyzing the chemistry of the greens to track nutrient changes. One of Tepper’s graduate students also secured a separate grant to convene consumer panels and measure consumer acceptance of the greens. The researchers will then track how different growing conditions change both the flavor and the nutritional content.

Even so, Tepper and the other researchers can only do so much.

“You can’t modify too many variables with too many treatments, because it becomes impossible, particularly when you’re doing sensory experiments.”

“You can’t modify too many variables with too many treatments, because it becomes impossible, particularly when you’re doing sensory experiments,” Tepper explained. “There’s only so many things people can taste at one time.”

Tepper signed a confidentiality agreement with AeroFarms, so she couldn’t go into detail about the experiment design, but she did say that “we had long discussions about balancing how many samples the panel can taste, how many variables…to modify at one time.”

For example: If Rutgers and AeroFarms are looking at light treatments and how different light recipes increase or decrease the presence of glucosinolates, it is difficult to also look at the role of temperature or different fertilizer mixes or carbon dioxide levels. For every variable tested, the group will need to have a control, otherwise it will be impossible to say whether any resulting changes in the plant are due to one variable or the other, or the two in concert.

Because there are countless variables to manipulate, these experiments can grow in complexity quickly, spawning endless permutations that take time and cost money. And that’s when a company has the benefit of a university research team and a giant research grant, which most do not. Of course, as Tepper points out, “you can do one set of experiments that focuses on one aspect and then come back and do another set of experiments that focus on a different aspect,” but the process remains arduous.

“Whether the average consumer is going to be able to differentiate, ‘oh, that arugula tastes extra special,’ I really don’t know.”

Do indoor farming companies really have the capacity to tweak light recipes and other growing conditions, then rigorously track how those tweaks manifest in the plant? In other words, do they really have the ability to grow finely-tuned, better tasting produce? Is it a science, an art, or just artifice?

While it might be relatively easy to see if herbs grow faster or slower, or bigger or smaller, greener or redder—subtle changes in flavor are much trickier to track, and not just for indoor farms.

“Whether the average consumer is going to be able to differentiate, ‘oh, that arugula tastes extra special,’ I really don’t know,” said Runkle.

And again, while AeroFarms and Rutgers will eventually publish some of their research in this area, most companies do all this work (or not) behind closed doors. We may always need to take their word for it.

“I hear about companies, indoor farming companies doing tasting studies,” Runkle said. “But the data is usually not shared or made available.”

“A lot of greenhouses, warehouses, vertical farming folks, it’s very kind of in the black box,” said Jon Friedman, the chief operating officer of the container farm company, Freight Farms, which supplied Square Roots with its first 10 containers. “And then you look and you’re like, it’s just lettuce, you’ve just grown lettuce, and you won’t tell anybody how you’re growing lettuce? Cool.”

—

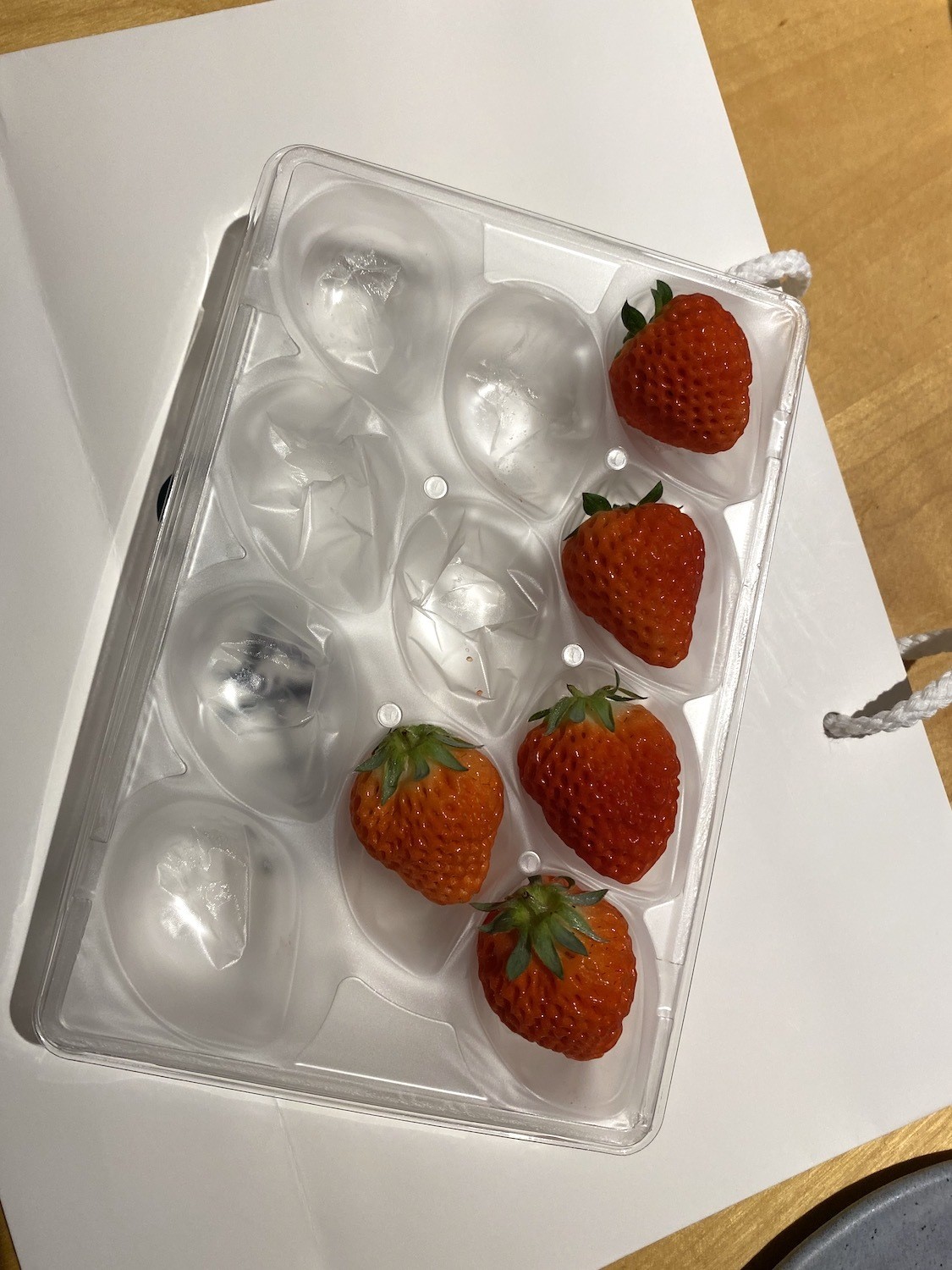

Oishii, an indoor farming company, recreates the “ideal natural ecosystems of Japan’s most distinguished strawberry-producing regions” to make its berries, which cost $50 a box.

OishiiOn a muggy July afternoon at the tail end of a heat wave, I took the subway from Brooklyn to Manhattan to pick up a $50 box of strawberries at Farra, a restaurant in TriBeCa. They’d been grown indoors in New Jersey by Oishii, the fruit company I mentioned earlier that models its farms on Japan’s strawberry-growing regions. (Oishii is a Japanese word that translates roughly to “delicious” or “tasty.”)

While the vast majority of indoor farms in the U.S. produce leafy greens or herbs, which are easy and fast to grow, tomatoes and strawberries have been bandied about as possible—and lucrative—future offerings. Musk said he thinks strawberries could be “the one that will blow people’s minds,” and his cofounder, Peggs, said he had researched strawberry production on a trip to Japan earlier this year.

Until I brought it up in conversation, neither Musk nor Peggs seemed aware that Oishii got there first—and have been selling vertically-farmed strawberries to restaurants since 2018.

The company says it is the only vertical farm growing strawberries on a commercial scale in the United States. John Reed, the company’s director of strategy and finance, said it is aiming to be the country’s largest strawberry producer within 10 years.

I wanted to taste the future of fruit.

Oishii sells boxes of eight larger or 11 smaller berries; I opted for the box of 11, so each berry cost a little over $4.50. They come nestled in individual cups, kind of like an egg carton, but suspended in plastic hammocks. They were a paler orangey-pink-red than I expected, with deep pockmarks but no seeds. They come chilled and should be stored chilled, but Oishii recommends bringing them to room temperature to fully enjoy their flavor and aroma (which was so potent I could smell it through my mask while riding the subway back home). While at Farra I also picked up a bottle of sparkling wine to go with the berries—not a true Champagne, but one made with grapes from an adjacent region; the bottle cost half as much as the fruit.

My tasting notes from that night were as follows: “Very sweet, like strawberry but more so, essence of strawberry, strawberry infused with strawberry, distilled strawberry.” But what was even more notable than the sweet taste was the texture, which was very soft, with a melt-in-your-mouth quality. My boyfriend described them as “light, smooth, and fluffy.” They were certainly superior to the commercial organic strawberries we later bought at the grocery store, but it was impossible to do a side-by-side comparison with the berries we might get in our CSA or at the greenmarket because the strawberry season had ended weeks ago.

Like Square Roots with its Genovese basil, Oishii says its indoor farms replicate the ideal environment for strawberries.

“I can’t go into the details, but the facilities are—you know, everything is tailored to the plants.”

“By recreating the ideal natural ecosystem of Japan’s most distinguished strawberry-producing regions in a controlled indoor environment, Oishii is able to consistently grow the world’s best strawberries year-round and pesticide-free,” the company claims on its website. “Oishii’s groundbreaking approach to vertical farming enables bees—nature’s pollinators—to thrive, ensuring optimal strawberry quality.” (Yes! Bees—and other indoor farms, including Square Roots, also introduce beneficial insects like ladybugs to help manage pests.)

In a video call, Reed declined to elaborate any more about Oishii’s farms or its growing conditions. “We manage our facilities in a dynamic way,” he said. “I can’t go into the details, but the facilities are—you know, everything is tailored to the plants.” Reed also said he could not divulge the specific variety of strawberry, which Oishii markets as the Omakase berry, after the chef-led dining experience. Omakase translates roughly to “I leave it to the chef,” Oishii’s co-founder told NPR. As with the dining experience, we have to trust the grower.

According to the company’s website, it is “a unique Japanese variety characterized by its beautiful aroma and exceptional sweetness. It was developed through years of breeding the best Japanese strawberry cultivars, resulting in its signature seedless appearance and creamy texture.”

Little is known about the genetics of Oishii’s berries—though the company calls its strains the Omakase Berry. (Omakase is a Japanese word that means “I’ll leave it to the chef.” )

Oishii

Oishii has taken a very different approach to marketing than other indoor farming companies. Instead of making the technology a centerpiece, it downplays the fact that the strawberries are grown indoors. Reed said the company does not share pictures or videos of the farms in order to protect its intellectual property. Instead of LED-bright, futuristic farming images, the company’s Instagram page is filled with sumptuous food photography, mostly—though not entirely—of strawberries, as well as other aspirational lifestyle content. It’s refreshing, in a way, that Oishii doesn’t celebrate the technology more than the unknown variety of fruit, because genetics remain the primary driver of flavor and texture.

But it’s also a reminder of an uneasy contradiction. At the same time vertical farming companies invoke a traditional growing heritage and the specificity of place, they tightly control the narrative about their own breeding practices and growing technologies. Since one can’t visit—or even see pictures of—the farms where Oishii’s berries are grown, and since one can’t know anything about the genetics it’s actually using, it serves the company to emphasize something else: time-honored agricultural practices honed in a different time and place. Maybe it’s a way to humanize the cold, technologized reality of indoor farming. Or maybe the stories are a way to compensate for a different anxiety: That these products are a kind of tabula rasa, blank-slate foods that could be from anywhere, or be anything to anyone.

—

Before light recipes and controlled environment agriculture, there was plant breeding, or the science of emphasizing desired traits through crossbreeding or hybridization—think Gregor Mendel and his peas. To ignore the role of breeding and focus singularly on light recipes or even the controlled environment more generally is to miss at least half the equation.

“In plant breeding, there’s two things we’re trying to work with,” explained Michael Mazourek, a vegetable breeder at Cornell University, in a phone call earlier this year. “It’s a genotype by environment interaction, and that really drives everything. There’s all the genetics of a species or forms within the species—cultivars or breeds. And then there’s everything in the environment—the fertilizer, the light, the growing season, rainfall or water supply. So it’s that interaction that’s going to determine a lot.”

The role of breeding, which is how farmers and scientists have historically developed fruits and vegetables with specific characteristics, is often downplayed by indoor farming companies. That, or they only mention the negative outcomes of breeding, like flavorless tomatoes that can travel long distances and still be red and firm—if watery and mealy—after weeks in transit and on the shelf. But plant breeding isn’t always as bad as all that.

Indoor farming companies typically emphasize their complex, climate-controlled growing conditions. But a plant’s genetics probably have more influence on flavor.

In his work at the University of Florida, Harry Klee studies how sugars, acids, and up to 20 different volatile compounds interact in tomatoes and other fruits and vegetables to produce what we perceive as flavor. For example, the volatile hexanal is characterized by a green and grassy odor; 1-nitro-2-phenylethane is musty and earthy; phenylacetaldehyde has a floral/alcohol scent; 2-phenylethanol is nutty and fruity; and methyl salicylate smells like wintergreen. Videos about Klee’s work show giant test tubes filled with jewel-toned tomato chunks ready to be analyzed using gas chromatography. Klee’s goal is to identify the primary genes that govern these volatile compounds and therefore the “flavor” of heirloom varieties and to use that information to help build (breed) a better-tasting commercial tomato.

I asked Klee to what extent light recipes can change the way fruits and vegetables taste, and how much control indoor farmers really have.

“While I’m sure light will have an effect on flavor, I don’t believe that anyone has really quantified it,” Klee wrote in an email. “Lots of growth factors do influence flavor. Salt, fertilizer, amount of sunlight, water . . . I don’t think anyone has systematically set out to define the variables.”

Jessica McKenzie

The author purchased Oishii’s boxed strawberries in New York City. Each Omakase Berry cost a little over $4.50.

Echoing Tepper, he said, “You have to appreciate that, to get useful data on flavor, one really needs to do this in a thorough way with consumer panels and these are expensive. It’s just a really complicated problem.”

In the end, the variety of seeds probably matters more than any light source or growing condition. “If you were going to take just some utilitarian tomato breed and [used] all your magic and hydroponics and all the tools available,” Mazourek said, “you’re never going to have, like, an exquisitely delicious tomato.”

But tweaking flavors and other characteristics in indoor farms can be susceptible to the same pitfalls as plant breeding. As in the Rutgers and AeroFarms experiment, making leafy greens healthier might also make them too bitter. A change that makes a plant sweeter could also reduce its shelf life, or lower its nutritional value. Improvements in taste could negatively impact yield, and vice versa. Who’s to say that an indoor farming company will always prioritize flavor over other more profitable characteristics, like yield, or faster growth?

Even if consumers get looped into the process, who’s to say that they know what’s best for them?

“If you just leave a consumer panel to their own devices,” Mazourek said, they’ll typically choose whatever is sweetest.

—

In spite of the limitations and challenges outlined above, interest in indoor farming’s potential remains sky-high, especially with those invested in space exploration. The National Aeronautics and Space Administration, for example, has funded research into indoor farming for years. “On the way to Mars, we’re going to take as many seeds as we can, but we can’t take all seeds,” Trent Smith, who leads the Veggie project at the Kennedy Space Center, said in a phone call earlier this year. “So if you can take a plant and then if you give it different light algorithms, you can change the nutritional composition of that plant, or you can change the taste of that plant, then you can kind of fine tune it for the crews’ preferences, or for the crews medical needs.”

One of the projects NASA has funded is a study of self-sustaining crop production by Freight Farms and Clemson University, which would come in handy in space, or in harsh climates that are unsuitable for agriculture.

“I don’t think we’ve seen the limits yet, we’ve just scratched the surface,” said Freight Farms’ Friedman. “There’s a lot of room to grow, pun intended.”

The NASA-funded study is a reminder that the rise of controlled environment agriculture over the past few years has been against the backdrop of climate change, which is often explicitly or implicitly evoked as a raison d’être for indoor farms.

Maybe the fantasy of perfectly-controlled climate farms is so compelling is because the actual climate—the one we live in—is anything but.

As Musk told me: “You can adjust [the light] spectrum by the minute, you can change the heat, you can create climate that is perfectly controlled.” If perfectly-controlled climate is the commodity indoor farms are selling, maybe the reason it’s so compelling is because the actual climate—the one we live in—is anything but.

It’s not enough that in an apocalyptic future, humankind will have indoor farming to fall back on. In the techno-utopian vision of indoor farming companies, their strawberries and basil will be as good as the best—almost no matter what befalls the earth. In this future, consumers don’t have to lose or sacrifice anything when climate change wreaks havoc on agriculture. If it’s too hot for strawberries to grow in Japan, that’s okay, because we can grow them inside in New Jersey, yours for just $50 a box. Even if you had to cancel your summer vacation to Italy because of a global pandemic—now increasingly likely due to climate change—you can still make pesto with basil grown in a “climate farm” inspired by Genoa.

It doesn’t matter, in this telling, if the science behind these flavor claims is still emerging. It doesn’t matter if we know little about what growing methods were used. It doesn’t even matter if, in the course of “improving” upon the conditions of 1997-era Genoa to grow better, faster basil, the indoor farm loses whatever tenuous connection it had to the “somewhereness” of the Italian countryside.

Genoa makes for a better story.