Photo by Marc Piscotty / Graphic by The Counter

A new class of fungi-based steaks, cultivated from a fast-growing micro-organism, may be a paradigm-shifting meat alternative. I visited Emergy Foods’ Boulder, Colorado headquarters for a taste.

A Boulder, Colorado-based startup has opened a new frontier in the world of vegan meat replacements. The company, Emergy Foods, announced on Tuesday morning the imminent launch of a brand called Meati Foods—the world’s first line of fungi-based steaks.

At first glance, Emergy appears to be another company jumping on the plant-based bandwagon. Across the food sector, well-financed companies are racing to replicate the taste and texture of animal protein without actually using meat. But this new offering is fundamentally different from Beyond Beef and the Impossible Burger. While most alt-meat products, from veggie patties to fake-chicken nuggets, approximate the finely minced texture of ground meat, Meati strives to emulate whole animal muscle. The result is geared more toward the steakhouse than the drive-thru. When I visited Emergy headquarters earlier this month—more on that experience in a minute—the product was plated with sautéed string beans and (vegan) mashed potatoes.

Emergy Foods’ fungi-based steaks are something new in the realm of plant-based meat alternatives. They’re not made from mushrooms, but from mycelium—the fast-growing fungal network that precedes a mushroom’s growth

Marc Piscotty / Emergy Foods

In a press release published Tuesday, the company calls itself “the first in market to produce whole cuts of plant-based meat in the form of steak and chicken breasts.” That’s a bit of a misnomer, though. Fungi aren’t plants at all, but a distinct, often-maligned biological kingdom with their own unique characteristics. While finished Meati steaks will contain a small amount of plant ingredients, they’re made mostly from filamentous fungi, a kind of fast-growing micro-organism that branches quickly into thread-like networks of cells called mycelium. (Citing intellectual property concerns, the company wouldn’t say which strain or species it is using.) The process means Emergy’s production procedure can take place entirely in a lab or factory, sidestepping agriculture completely, and opening up a new universe of sustainability implications.

The company was founded in 2016 after two PhD students at the University of Colorado, Boulder, decided to apply their scientific expertise to the realm of food. Justin Whiteley, a mechanical engineer focused on materials science, and Tyler Huggins, an environmental engineer, spent their higher-education careers studying the ways biology might be used to create hyper-efficient new products. Together, the two have co-authored more than a dozen studies on a range of topics, including renewable lithium batteries, charcoal-based water filtration systems, and the ways fungi can be used to bioremediate highly polluted environments. Huggins tells me the pivot to food was a way to maximize impact, though it’s unclear whether he means the environmental or economic kind. You couldn’t blame the pair for seeing dollar signs: According to data from the Plant-Based Foods Association, an industry lobbying group, U.S. sales of plant-based meat are up 10 percent since 2018. Emergy Foods is riding the wave of that excitement, raising 4.8 million dollars in venture capital from eight investors this July.

Tyler Huggins, left, and Justin Whiteley, the co-founders of Emergy Foods

Emergy Foods

While the U.K.-based company Quorn has been making mycoprotein—protein from fungi—for decades, that company’s “beef” products are ground or cut into small strips for tacos or stir-frys. Emergy is the first company attempting to use mycoprotein for a truly steak-like fake meat, something you might enjoy in a restaurant with a white tablecloth. Still, Huggins points out that his company’s proprietary production process has some similarities to traditional foodmaking techniques used throughout the world. Miso, soy sauce, and sake are all made by fermenting soy or rice with mold spores known as koji, or Aspergillus oryzae, a filamentous fungi prized in Japan. And Tao Zhang, co-founder of the plant-based impact investing firm Dao Foods International, says Chinese cuisine has long used fungi to impart a meaty flavor to otherwise vegetarian meals.

But while those methods use fungi to ferment or flavor plant material, Emergy’s approach is different. In its case, the fungi are not a processing agent, but the final product. The company grows its own mycelium in a submerged fermentation process, feeding them on sugar water. The approach is a little like cheesemaking, Huggins says, since the product is cultured in large stainless steel vats, then harvested. Fungi-based meatmaking also superficially resembles the still-experimental process used to produce cell-cultured meat, an emerging approach that entails growing animal cells inside large bioreactors. But, Huggins says, fungi have a major advantage over their animal-cell cousins.

“Animal cells don’t have their own digestive system,” he says. “They don’t have the capabilities, the mechanics to actually break down complex carbohydrates or sugars into something that they can use as energy.” After all, isolated cattle cells in a test tube lack the stomach the full-grown animal has.

Emergy’s production procedure can take place entirely in a lab or factory, sidestepping agriculture completely.

“That’s where fungi come in,” Huggins continues. “They are very versatile because they have their own digestive system. They can break down a variety of different carbon sources, sugar sources in order to convert it into energy and ultimately grow and produce more proteins.” Fungi come naturally equipped with the biological capabilities cultured meat startups are still trying to get animal cells to replicate.

At the same time, the ability to subsist on sugar water may give fungi steaks a sustainability advantage over plant-based burgers. Standard plant-based meat replacements tend to be made of soy, wheat, and pea protein, as well as other grains, legumes, and pulses. These commodity crop ingredients not only require lots of land to grow, which can lead to deforestation, but they also tend to require synthetic fertilizer, herbicides, and insecticides, which can lead to environmental problems of their own.

Huggins says that his mycelium, in contrast, can live on ingredients other companies might throw out. In theory, he imagines a system where he can feed his fungi on the sugar-water created as a byproduct of the beer-making process—a natural resource that is in abundance in Colorado. Since the Brewers Association, an industry trade group, estimates that breweries waste seven barrels of water for each barrel of beer produced, Emergy could become a badly needed customer. From there, Huggins says, the production process creates no waste byproducts that can’t be plugged back into the system—for instance, residual sugar water that can be fed back to the fungi.

“Basically, we just need a sugar source,” Huggins says. “That’s true whether we buy that at a grocery store or, ultimately, down the road, partner with another food or beverage processing company and use their residual sugar that goes to waste. That’s still food grade, and still very nutritious. We could use that as a feedstock and create a truly circular-based protein production process. That would be a game-changer in this space.”

Meati Foods, the public-facing brand of startup Emergy Foods, plans to start selling fungi-based steak products to restaurants in early 2020

Emergy Foods

In an interview by email, Nicole Civita, an attorney and educator who leads the sustainable food systems curriculum at the University of Colorado, Boulder, expressed some doubt about this approach.

“I’m a little skeptical about the notion that the ‘sugar water’ feedstock can be sourced via brewing by-products, as the brewing process generally consumes the sugars in the grains,” she writes. “But maybe I’m misunderstanding the intended sugar-source here.” While the Brewers Association writes that brewery wastewater can contain sugars, proteins, carbohydrates, and yeast, it’s yet unclear whether that supply would be consistent enough to feed Emergy’s mycelium. Still, Civita feels the company’s model may one day fit nicely into a larger landscape of sustainable food sources.

“While I am not in a position independently assess the claims being made about Emergy’s products, I can say that I believe that there’s a place for vat-grown mycelium-based protein sources in healthy and sustainable diets,” Civita writes. “The shorter and relatively simply supply chains they describe are appealing because they have the potential to be far less input and energy intensive than other traditional animal protein sources and plant-based alts. The sustainability proposition gets even stronger if the mycelium can be safely and efficient grown out using co-products from other food manufacturing processes.”

As they grow, the mycelium also naturally solve another problem cell-cultured meat companies are still struggling with: the challenge of mimicking muscle tissue. When replicated in a petri dish or steel vat, animal cells make only more animal cells, and not sinew, tendon, muscle, bone, or fat—the things that make a steak feel like a steak. That’s why the experimental cell-cultured meats currently being developed (and fed to curious reporters) tend to be foods like sausages and chicken nuggets, which can absorb a certain amount of shapelessness. While scientists are exploring a number of methods to make cell-cultured meat more steak-like, including using scaffolds made from decellularized plant husks, they haven’t yet succeeded. But Emergy’s mycelium naturally grow with a structure that lends itself to the steakhouse.

“It’s not easy to do and it’s taken us almost over two years in order to develop,” Huggins says. “But what’s so great about mycelium is it has a fibrous nature that mimics muscle structure.”

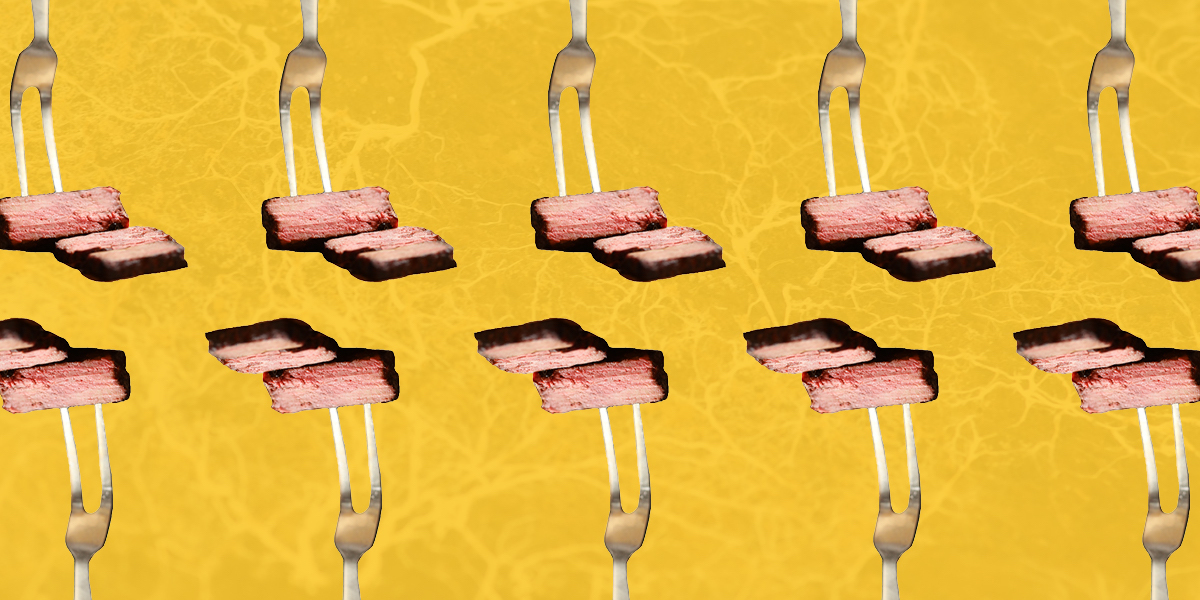

Fungi-based mycoprotein may have a more inherently meat-like texture than plant-derived protein. Left, a beef-like Meati “steak.” Right, Meati “chicken” strips

Marc Piscotty / Emergy Foods

While the texture is more inherently meat-like, Emergy faces a different hurdle: taste. While plant proteins can be broken down into different molecular components, isolating or highlighting certain sensory characteristics, mycelium tend to have no flavor. When I asked an Emergy spokesperson about this, she confirmed that the product’s main ingredient is tasteless. It’s a completely blank gustatory canvas.

The challenge, then, will be to make Meati steaks taste like something people want to eat. Huggins suggests that, eventually, the company may be able to impart more flavor through the fermentation process. For now, it uses a variety of vegetables and spices to create flavor; the final product, which Emergy says includes fewer than five functional ingredients, is a blend of 90 percent mycelium and 10 percent other ingredients. Emergy wouldn’t tell me the exact recipe, citing the fact that the formula is still evolving. But company representatives did confirm Meati products aren’t made with soy, wheat, or pea protein, which tend to be primary ingredients in plant-based alt-meats.

What does the result actually taste like? At a private lunch hosted by the company last week, I found out.

Emergy’s headquarters is located in the Gunbarrel Tech Center, an office park a few miles north of downtown Boulder, where IBM copier machines were once manufactured. I saw logos for other local food and tech startups plastered on windows as I passed.

At the door, I was greeted by Morgan Agho, Emergy’s director of marketing, who came to the company from Boulder Brands, the maker of Earth Balance plant-based buttery spreads. On the walls of the small, open floor-plan office—enough to house the company’s team of eight full-time staffers, five of whom have PhDs—large windows allowed a glimpse into Emergy’s modest manufacturing facility. Employees wearing blue food safety hair nets worked behind the glass. Beakers of liquid, presumably holding microscopic fungi cell, shook on swiveling trays, an aerating process that helps cultures incubate.

Agho took me into a side conference room, where containers of cantaloupe-colored mycelium—not for eating, Agho said, but the result of some staffer’s experiment—collected in thick, cobwebby pillows on each windowsill. My meal was quickly brought out on a wooden cutting board: a mass of green beans, a large scoop of mashed potatoes, and six small cuts of steak. From where I sat, the texture actually looked quite steak-like, though the livid pink color made the experience feel more otherworldly than familiar.

Agho said that these steaks had started growing the previous night around 5:30 p.m. The process takes about 20 hours. The fungi multiply so quickly that, ultimately, she said, a full-scale Emergy facility will be able to produce the protein equivalent of 4,200 cows a day.

With that, it was time to eat.

A view of the fungi-based meal I was served at Emergy Foods’ office

Joe Fassler

The first thing I noticed was the way the outside of the meat managed to singe and crisp much like a real steak would, with a feel on the teeth and tongue like muscle seared on a grill. The steak’s flesh—I should say “flesh”—had a mild, savory flavor that was not unpleasant. It did not especially call to mind the taste of steer or, for that matter, mushrooms. It was slightly reminiscent of a soy nugget, with a subtle hint of malt.

More interesting was the texture. The cuts weren’t bouncy, like a portabella mushroom, or spongy like soy protein. Yet they definitely lacked the layers of connective tissue that makes steak break into tender strings across the palate. The protein felt dense and tender and juicy, though it was hard not to miss the unmistakable blast of salty flavor that comes from biting into something pink and medium-rare. The overall affect was enjoyable, if subtle. But I never felt like I stepped into the uncanny valley.

The Meati steak’s “flesh” had a mild, savory flavor that was not unpleasant, though it didn’t especially call to mind the taste of steer

Joe Fassler

That allowed doubt to creep in. The more I thought about it, the more I struggled to classify my experience, scribbling phrases in my notebook, reaching for descriptions that made sense. That strangely unsettled feeling helps explain why Emergy used the term “plant-based” in its press release, even knowing the label doesn’t quite fit. It wants to provide customers with a comforting reference point, a way to make its product not feel quite so unfamiliar and new.

In our email interview, Nicole Civita explained further.

“Unfortunately, such foods are notoriously hard to market—‘fungal foods’ doesn’t sound terribly appetizing! And it’s not accurate to describe the protein rich foods made from mycelium as ‘mushroom-based’ either, because they are made from the precursor to mushrooms, not mushrooms themselves,” she wrote. “So, companies in this space have struggled to describe their products in ways that are both accurate and appealing. And sustainable food advocates have favored the less accurate and insufficiently encompassing “plant-based” vernacular. While this drives biologists crazy and could run afoul of food labeling regulations, lumping myco-foods in with the plant-based alts is a reasonable shorthand.”

Maybe that shouldn’t matter. If the goal is to create a low-impact food source—and if Meati steaks really have the benefits its founders claim—then who cares if its steaks taste like the ones we grew up with? The challenge for Emergy, though, is that it’s going for a kind of holy grail here, trying to emulate the protein we eat at our plate’s center, unadorned. Even an Impossible Burger can hide behind its bun, distracting us with lettuce and tomato, or cheese, or whatever special sauce Burger King puts on its Whoppers. A steak just sits there, naked.

“The theory of change of Impossible Foods and Beyond Meat is to just make life as easy as possible for the meat-eater by replicating price, taste and convenience,” says Pete Newton, a professor of environmental studies at the University of Colorado, Boulder. (I’m auditing his graduate seminar on the environmental impacts of food production this semester.)

“If you can just drop in an alternative that is plant-based—or mushroom-based—then you’re asking very little of the consumer. But the second you start asking them to compromise on experience or taste or texture, then, the theory of change goes, it would be harder to convince large swaths of the population to start consuming it. I’d be curious to know from the Emergy folks what their aim is in that regard. Are they trying to create a product that is indistinguishable from meat? Or are they just doing something that’s good, and will capture some people, without being particularly committed to the cause of being able to compete in a blind taste test?”

My sense, based on interviews and promotional materials, is that the company has its sights on the bolder, more difficult task of going head-to-head with steer muscle. And a limited number of Americans will soon get a chance to decide whether they’ve pulled it off. In just a few months—the first financial quarter of 2020, according to Huggins—Emergy Foods will pilot its first steaks in a select group of restaurants, likely in the Boulder area.

“It’s a great way to give consumers the opportunity to try something that they’ve never tried before,” he says. “A restaurant’s a great place to do that. Then, once we can get enough acceptance in the market, and people are talking and excited about it, and we can build up scale, that gives us the opportunity to move into retail.”

A steak is more than just delicious. It has always been an invitation to something primal, a way to press our teeth directly into flesh and be reminded that what we are eating was once an animal—that we, too, are animals. That may be an integral experience, or a problematic one, depending on your view. But the fact is, when I bit into a Meati steak, I mostly felt uncertain. What system, what network of relationships, was I joining myself to through food? The taste was almost irrelevant. I wasn’t yet sure how to feel.

Not that we can’t be convinced. Time will tell if that ambiguity—rooted in the blank, flavorless texture of its still-mysterious main ingredient—is something Emergy Foods can overcome.