Sarah Chadwick Gibson

At the outset of the salmon season, fisherman Everett Thompson was looking forward to a banner year. The Alaska Department of Fish and Game had estimated that 41 million wild sockeye salmon would come to Bristol Bay, an eastern nook of the Bering Sea formed by the Alaskan Peninsula. Ultimately, 59 million salmon returned—the most since 1980—leading to record hauls in parts of the region, which contributes 40 percent of the world’s annual sockeye harvest.

For a state that prides itself on sustainable salmon and ranks its seafood industry just below oil and gas, this should have been good news. As the annual migration reached its peak around July 4, Thompson and his deckhands were netting 15,000 pounds of salmon in six hours. Then he got an unexpected call from the plant manager. The message: Stop fishing.

“I was like, did I hear that correctly?” Thompson says.

Like hundreds of other fishermen this year, Thompson was placed on limits because his processing facility couldn’t handle the volume. Simply put, there were too many salmon, and not enough workers.

Convincing seasonal workers to come to the most remote corner of the United States has never been easy. But this year, immigration policies, difficult labor conditions, and the unpredictability of wild salmon combined into a perfect storm. Experts estimate that the labor shortage cost Bristol Bay’s fishery tens of millions of dollars in lost profits. (In this context, the term “fishery” doesn’t refer to a specific processing plant—it’s how the industry describes the entire network of fishers and processors targeting a species within a single body of water.) Until a better plan for recruiting and retaining employees is developed, Bristol Bay risks not having the staff to process its fish.

Everett Thompson

Everett Thompson Everett Thompson was told to stop fishing at the peak of the season

Working the slime line

Bristol Bay is the world’s largest sockeye fishery. Fed by vast tundra rivers, it sees 18 hours of sunlight in the summer and 30-foot tides each day, and up to 50 million sockeye return from the ocean each summer to spawn. The human population, meanwhile, is too sparse to handle all that fish. A few hub towns and Native villages dot the region—only about 7,500 inhabitants in an area roughly the size of Kentucky.

Each June, a fleet of around 1,500 boats, owned mostly by fishermen from Alaska and Washington, sets up for harvest at the rivers’ mouths. Fishermen fly in deckhands—and, to keep pace with the volume, seafood companies charter planes to fly in about 4,500 processing workers. Of those, only about 15 percent come from Alaska.

In a good year, Bristol Bay’s isolation and grueling work pay off. In about five weeks, a processing worker can make $5,000 with minimal expenses; a vessel with three deckhands and one captain can reel in $300,000 before expenses. Still, enticing workers is an ongoing challenge.

Brian Gannon has been recruiting workers to Alaska’s seafood processing plants for over 20 years. He used to get a lot of college students from the U.S. and abroad, but now he says a job fair in a big city can yield just a handful of workers. He blames increased government labor restrictions and reduced appetite for manual labor among young people.

“I don’t know where you find people,” Gannon says. “I’ve recruited in Guam, Samoa, the Virgin Islands, and 40 states in the lower 48, [but] soon it’s going to be just us recruiters in a room talking to no one about how great work in Alaska is.”

“Great” is subjective when it comes to a salmon processor gig. Room and board cost just $10 a day, but the pay is low: $10 an hour, $15 for overtime. Many say that the fishery’s slim profit margins won’t allow for a wage increase. Worksites are isolated, accessible only by boat or plane from Seattle or Anchorage.

Screenshot

Screenshot A news clipping from a job fair in American Samoa, where Alaskan recruiters look for labor

A worker I’ll call “S.” came to Alaska for one of these jobs. He didn’t want his name used because he says he hopes to work at the same processing plant next summer, and his boss discouraged him from talking to media. For recruiter Brian Gannon, a worker like S. is a rare find—a U.S. citizen who, because of seafood companies’ million-dollar recruitment efforts, heard an ad on the radio, passed the background check, and got on a plane to Alaska.

“It’s mandatory 16-hour days,” S. says about the work. The slime-line—where fish are cut and eggs and guts extracted—is notorious. “You tend to get the most blood and guts on you there. Some people consider it torture; others consider it just another job.”

S. found the work “brutal” but satisfying; he survived the summer without any injuries, got along with his bunkmates, and got paid regularly. But his experience isn’t universal. Some workers, he says, went daily to urgent care for minor injuries. Others paid their way back home because the job was so exhausting. In another plant, Puerto Rican workers left early and reported abuses and injuries that prompted an OSHA investigation. (New Food Economy has reported on the growing reliance on Puerto Rican manual laborers under the Trump administration.)

The fact is that it can be dirty, dangerous work—and it can be hard to find people willing to travel to Alaska to do it.

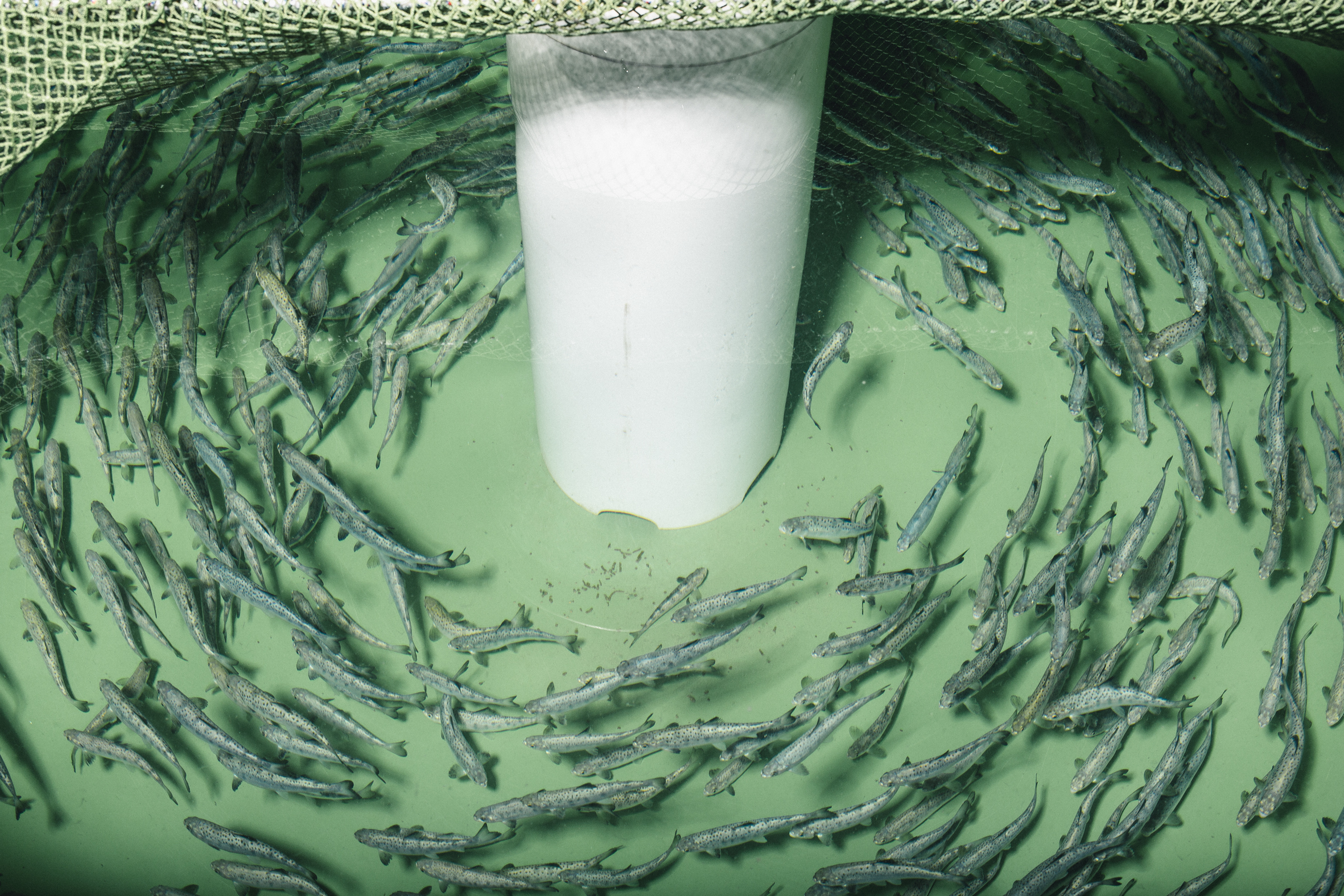

Everett Thompson

Everett Thompson Alaskan Sockeye salmon

To H2-B, or not to H2-B

Senator Lisa Murkowski (R-AK) has promoted a solution often invoked by the state’s seafood industry over the years: If there aren’t enough Americans like S., the government needs to increase the number of H2-B visas for Alaska to hire foreign workers.

Each year, businesses can apply for H2-B visas for “non-agricultural seasonal workers,” a category that includes everyone from slime-line workers in Alaska and crab-pickers in Maryland to the landscapers at President Trump’s Mar-a-Lago Resort.

But the H-2B program is a flawed solution for Alaska.

By the time seafood processing companies can apply for H2-B visas, much of the country’s quota of 66,000 has already been doled out to other states with seasonal work that starts earlier in the year. This has become an issue in the fisheries elsewhere in the country—this year, the Gulf of Mexico’s shrimp industry also couldn’t get enough H2-Bs to staff its boats. A combination of new cap rules and increased concern about workplace Immigration and Customs Enforcement (ICE) raids made H2-B visas an especially hot commodity this year.

January 1 was the first day Alaska seafood companies could apply for visas for summer workers. By March, all 66,000 were spoken for.

In 2016, Brian Gannon got 1,800 H-2B visas for seafood workers in Alaska; this year, he got 200 for returning workers and zero visas for new recruits.

At a meeting of the Senate Appropriations Subcommittee on Homeland Security on May 25, Senator Murkowski requested more last-minute visas. With fishermen readying for harvest, processors reporting a labor shortage, and salmon swimming towards Bristol Bay, Murkowski urged the government to time visas with fish biology, not the other way around. “The salmon don’t care when the permits are issued,” she told John Kelly, then-Secretary of Homeland Security. “They don’t care whether or not we’ve got processors in place.”

Critics say that the H2-B program is too broken to expand as Murkowski proposed. There are years of documented workplace abuses—mostly reported in the lower 48—and economic evidence that the program encourages artificially low wages.

Daniel Costa of the Economic Policy Institute says that not all industries citing labor shortages in their H2-B applications can prove it. There are two main indicators for a labor shortage that truly requires foreign workers: 1) low regional unemployment rates and 2) increased industry wages. Alaska doesn’t meet either of these criteria. It has the country’s highest unemployment rate, and wages for processing workers have been stagnant for years. So the reality may boil down to a simple truth: When native-born Americans are no longer willing to work the very dirtiest jobs for minimum wage, businesses are forced to turn to non-citizen workers.

Processed fish are tossed into a “gut bucket”

Contending with a fickle fish

But there’s another powerful character that complicates this drama: the wild salmon themselves. Despite the science available to estimate summer returns, the sockeye population is unpredictable. Processing plants never know on which day—if any—they’ll need the maximum amount of workers. And even if they could find willing employees, it would be hard to determine how many they’ll need.

“At the beginning of the day you don’t know if you’re going to get 200,000 fish, 1 million fish, or 2 million fish,” says Gunnar Knapp, an economist who studies Bristol Bay. “The people in the head offices and the fishermen just don’t know what this afternoon will bring.”

To some extent, this unpredictability has thwarted the industry’s attempt to create systems that would add value to the salmon and create more revenue for fishermen.

Everett Thompson

Everett Thompson An Alaskan fishing boat

Icicle Seafoods and Silver Bay Seafoods are two of Alaska’s biggest companies that traditionally hire H2-B workers. This year, both had set up plants so that workers could fillet salmon rather than just head and gut them—colloquially called “H-and-G-ing.” H-and-G fish typically go to China or Japan to be filleted, then are sold in markets in the U.S. and Asia.

Brian Gannon, the labor recruiter, suspects this value-added step of filleting in Bristol Bay would have more than doubled the fishery’s profits. It also would have simplified the sea-to-consumer chain. But it requires patience, skill, and more time from workers—and when labor turned out to be in short supply, the companies were forced to abandon their more ambitious plans. Ultimately, they scrapped filleting entirely and resorted to H-and-G-ing and canning instead.

At that point, Gannon says, “You’re going fast but it’s not your processing plan. You’ve abandoned everything so you’re losing literal dollars on every fish that goes through.”

Not all fishermen suffered from the labor shortage. Thompson says that while at anchor, he talked to friends who had contracts with different companies and didn’t have severe limits. Knapp, the economist, says Bristol Bay’s size and ecology make that variation unavoidable. If you’re fishing for a processor that can process only 600,000 fish per day, “when there are 1 million fish in a day, a processor will say ‘we can’t buy them; we’re full.’ And the next day the fishermen are out there screaming: ‘My buddy is fishing for another processor and having the season of his life!’”

Thompson wants processing companies to focus on recruiting and paying workers so that the plants operate at full capacity from June 27 to July 15. It’s a short window of time with limited appeal unless the wage increases.

But Gannon doesn’t think the profit margin for wild salmon will allow for that. When asked how the fishery would survive without an influx of H2-B workers, Gannon said he guessed processors would stop looking for 4,000 workers and “spend 50 million at the plant to use robotics.”

Until fisheries find a better labor solution, painful repercussions from this year’s labor shortage will continue.

Thompson estimates that the number of days he was placed on limits cost him about $128,000, which is a third of the crew’s possible income. “If guys had been able to fish without limits for the summer,” Thompson laments, “they would have had the best summer of their career.”